Reliable debarking – no risk of knife breakage!

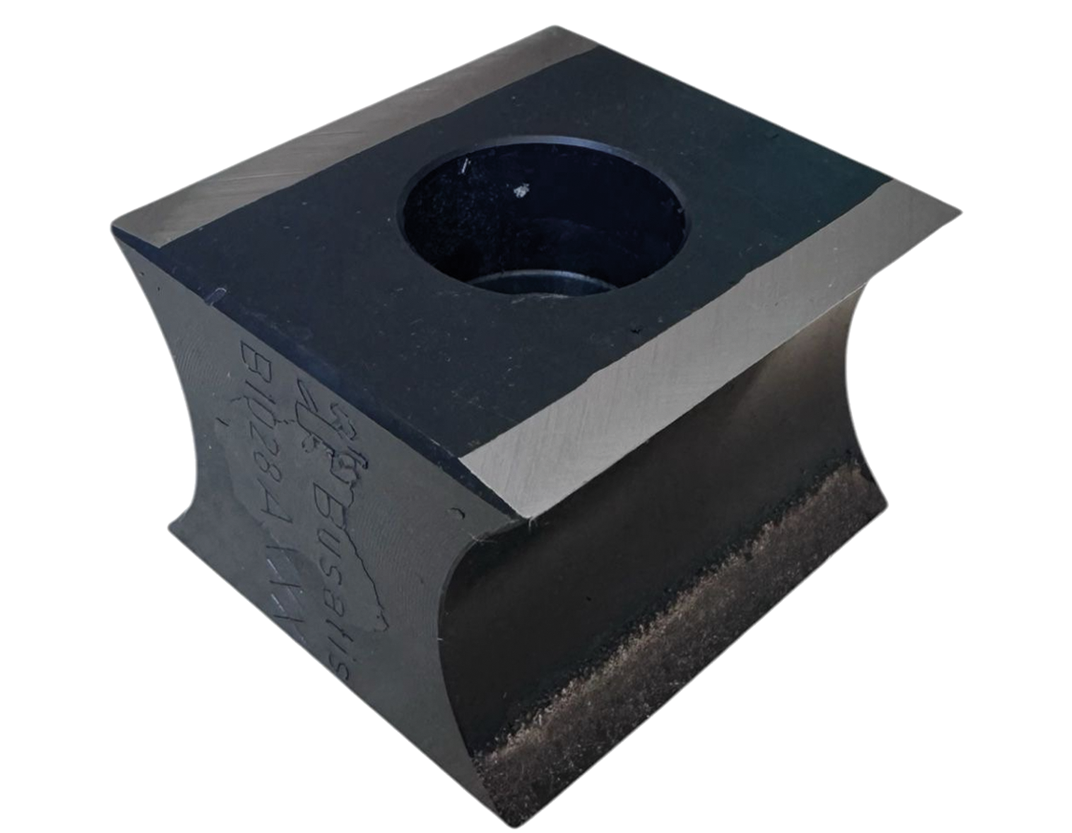

Maximum Service Life. Zero Compromises. In collaboration with Busatis, we offer cube knives and high-performance debarking knives – with no use of carbide at all.

Thanks to specially developed technologies, we rely on a wear-resistant peeling edge created through plasma powder surfacing (plasma-transferred arc welding).

The result: knives with an exceptionally robust edge – even when subjected to impacts, foreign objects, or frozen wood.

Benefits for your sawmill:

- Consistent performance regardless of temperature

- Reliable across all common wood types and at high feed rates

- Exceptional durability under extreme conditions

- No brittle fracture behavior as seen with carbide tools

Choose long-lasting quality – for reliable processes in debarking and wood processing.